Rose Kitz

Musical Instrument Maker / DSP & Acoustics Explorer / Mechanical Engineer / STEM Educator

Musical Instrument Maker / DSP & Acoustics Explorer / Mechanical Engineer / STEM Educator

![[to add dog pic]](assets/img/portfolio/robot_dog/robot-dog-card.png)

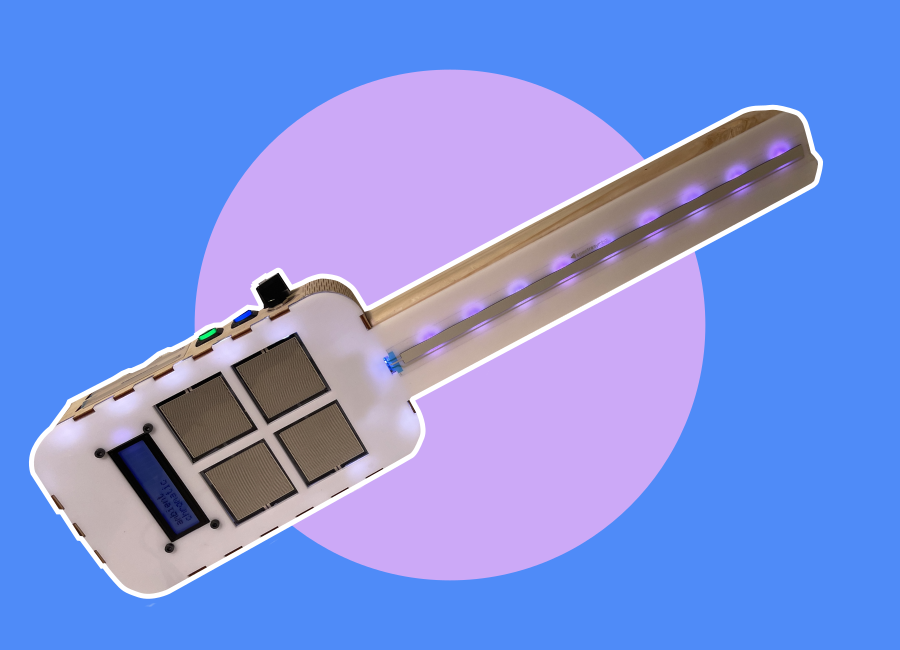

I just graduated from Tufts University, majoring in Mechanical Engineering with a minor in Music Engineering, focused on acoustic instrument design (check out the trombone I designed & built this past semester!).

Throughout college, as a creative student, welcoming staff member at Tufts' community makerspace, and year-round varsity captain of the cross country and track & field teams, I was constantly adapting, balancing, compromising, and communicating with others to engender a sense of community & improvement in every facet of life.

I spend my time tinkering with found materials, exploring access to design for creators & users, and figuring out how to effectively & joyfully communicate about engineering concepts. You can also find me staring at ceilings, listening to walls, and clapping at random (I'm insatiably curious how and why things sound the way they do).

I believe that everyone is an expert -- of their own experience -- and it is therefore imperative, as an engineer myself, to seek out, listen to, and embrace others' perspectives in the design process. Everyone has a seat at the table -- and in every moment back to the drawing board.

rose.c.kitz@gmail.com

Please reach out if you'd like to

learn more about me/my projects/background, I would love to hear from you :)